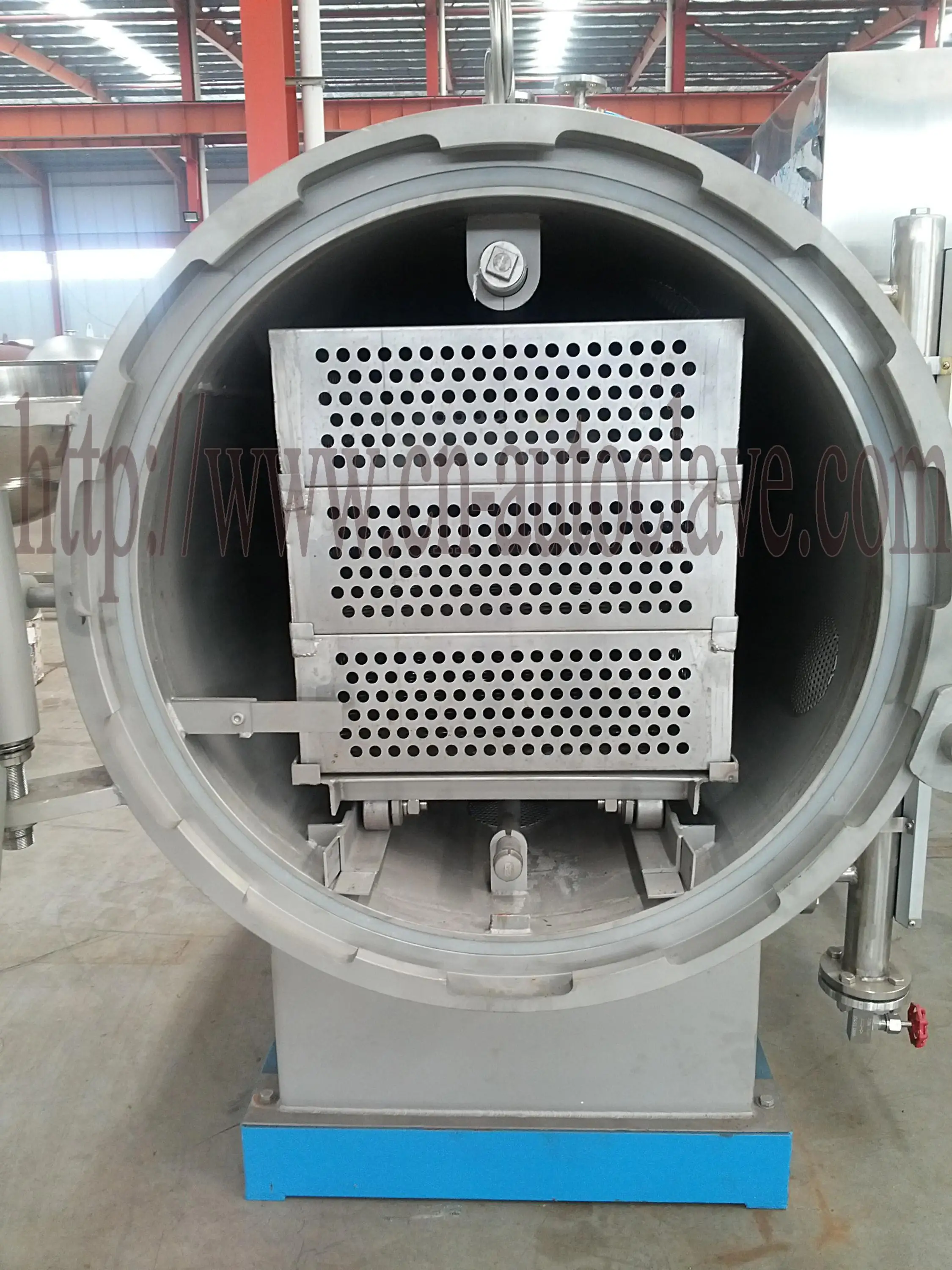

Industrial Food Retort / Sterilizer For Vacuum Fresh Corn

1. Product Description

A. It is high pressure and the transferring temperature is much higher than the boiling water.

B. It uses certain medium (called as heating medium or sterilization medium) as a tool to transfer heat for product. The medium can be steam, hot water and the mixture of the steam and air.

C. Some systems use over 0.1MPa excessive pressure during sterilization and cooling to maintain the integrity of the container and balance the pressure inside the tank. It aims at semi-rigid plastic container with heat sealing, soft bag, metal plate, cardboard and glass containers.

2. Applicable Scope:

Suitable for meat, eggs, corn, peanut,vegetables, bean products, aquatic products, edible fungus and other food sterilization. Mainly used for meat canned food.

Canned Food: Tin canned, aluminum cans (almond, walnut, healthy tea beverage etc.)

Soft Packaging: aluminum foil bag, transparent bag, vacuum bag, high temperature cooking bag

3. Working Principle & Features:

The double-layer water-bath autoclave inputs the heated sterilization water from the top storage tank to the below sterilization pot, soaking the food, while using circulating pump to make the hot water flow cyclically. In the process of flow, the steam is heated continuously to a preset temperature, so as to achieve the purpose of heating sterilization. After the completion of the sterilization, the hot water will be back to the storage tank. Cooling water comes from the outside into the pot directly and finishes cooling.

Features:

2. The product is completely immersed in water, and the temperature can heat the product from all directions.

3. During the whole process, products can not touch the air so that there is no air mass in the retort. Optimized circulating water system ensures even heating distribution in the sterilization pot.

4. Control the back pressure by controlling the in and out of the compressed air, thus avoiding the pressure peak and greatly reducing the damage to the packaging material.

5. Smooth, gentle, but rapid cooling avoids thermal shock and cooking smell of product.

6. In the heating process, the heat can be passed into the product by the fastest speed, to ensure the desired sterilization effect and achieve the desired F value.

7. It is equipped with two movable temperature sensing probes, which can monitor the F value of the food center at any time and the heat distribution in the sterilization pot.

4. Technical Parameters:

This model is SC12-2.B.3, inner diameter is 1200mm, vessel length is 2000mm, Outside measurement is 2800mm long, 1400mm wide, 2000mm high. The thickness of autoclave is 5m, max working pressure is 0.3Mpa and max working temperature is 145℃.

Water bath autoclave/retort/sterilization pot |

|||||||||

Model No. |

Outside Measurement(mm) |

Inner Diameter(mm) |

Vessel Length(mm) |

Capacity(m³) |

Thickness of Autoclave(m) |

Max Working PRE.(Mpa) |

Max Working TEP.(℃) |

||

Length |

Width |

Height |

|||||||

SC.12 -2.B.3 |

2800 |

1400 |

2000 |

1200 |

2000 |

2.65 |

5 |

0.3 |

145 |

Water Pressure Test Before the Insulation

Pressure to test the water, check there is leak or not in the tank.

If there is serious water leakage, stop the water pressure test and repair it.

Insulation process of the autoclave

Firstly, drilling holes used in the following steps in the tank in advance.

Secondly, put steel rings welded on the tank. The rings are used to fix the mineral wool.

Thirdly, use mineral wool, the material of which is aluminium silicate, to wrap around the tank body for preservation.

Lastly, use insulation board to be welded around the tank. It is finished.

6. Packing & Delivery:

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

Before delivery, our professional technician will do trial run for each product to make sure no problem, you can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with steel wire rope so that the retorts can't move arbitrarily in the container.

>One year free warranty

>Technician-online support

> E-mail, CD/ DV or software to solve detailed questions.

8. Company Introduction

Shandong Zhongtaida Industrial Equipment Co. Ltd. is a key enterprise which design, research and produce high temperature sterilization pot and sandwich pot. There are 150 staff in which there are 5 senior engineers, 8 intermediate engineers, 10 designers, and other 65 technicians with professional knowledge and operating skills. Over the years, our autoclaves and sandwich pot sells well in China, Russia, Southeast Asian countries, winning the praise of customers at home and abroad. LONGWANG autoclaves have computer full-automatic/semi-automatic showering autoclave, computer full-automatic/semi-automatic double-layer water-bath sterilizer, single layer water-bath autoclave, single layer steam autoclave, double-connecting full-automatic/semi-automatic autoclave, hot water type sterilization, electric &steam autoclave, electric heating sterilization for laboratory, universal cooking sterilizing, rotating type autoclave and so on more than 10 series and 200 varieties. We can also design non-standard products according to the different needs of each user specifically.